Alfa Powder Coating

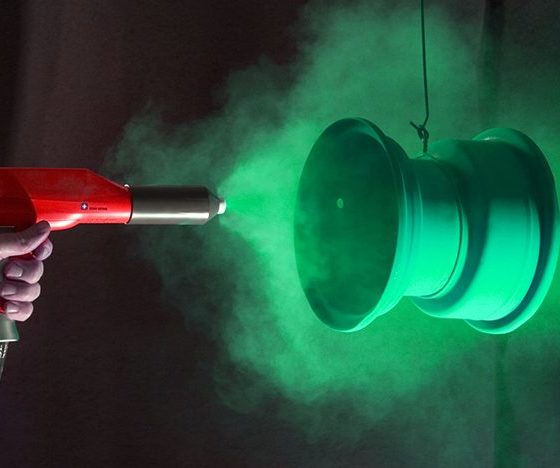

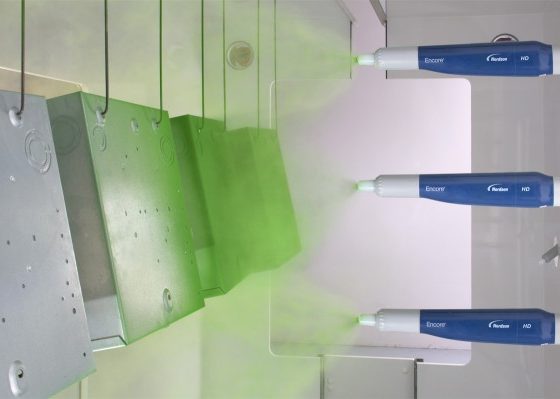

WELCOM TO ALFA POWDER COATING Powder coating is a modern, more environmentally-friendly alternative to traditional wet painting. Minute powder particles are applied to a metal object or component using an electrostatic spray process, which causes the powder to adhere to the metal surface. After spraying, the component is cured in an oven at up to 200°C. This process then melts the powder onto the metal creating a highly finished and durable coating.

About Powder Coating

Powder coating is by far the youngest of the surface finishing techniques in common use today. It was first used in Australia about 1967.

Powder coating is the technique of applying dry paint to a part. The final cured coating is the same as a 2-pack wet paint. In normal wet painting such as house paints, the solids are in suspension in a liquid carrier, which must evaporate before the solid paint coating is produced.

In powder coating, the powdered paint may be applied by either of two techniques.

- The item is lowered into a fluidised bed of the powder, which may or may not be electrostatically charged, or

- The powdered paint is electrostatically charged and sprayed onto the part.

There are two main types of powder available to the surface finisher:

- Thermoplastic powders that will remelt when heated, and

- Thermosetting powders that will not remelt upon reheating. During the curing process (in the oven) a chemical cross-linking reaction is triggered at the curing temperature and it is this chemical reaction which gives the powder coating many of its desirable properties.

We have had several conversations recently about the benefits of powder coating vs painting.

What exactly is powder coating? And why is it more durable and longer lasting than paint?

The material that most powder is made from is basically “plastic”. Polyesters are chemically related to plastic and have an extremely strong chemical bond. Some may remember the wonderful but hideous polyesters of the 1970s. While some inexpensive polyesters and plastics are rigid and brittle, there are many forms of plastic such as kevlar, nylon and plexiglass that are strong and flexible. The molecular bonds that make plastics so durable also make them extremely resistant to the natural process of decomposition. This is one reason why powder coating is so long lasting.

Most quality powders are made from pure or blended polyester resins. These start out in liquid form and are poured into molds to dry. Imagine a huge ice cube tray. Then the blocks of dried resin are ground into a fine powder by a giant blender. Different colors can be made by mixing pigment during the liquid resin stage or by mixing powders. The multitude of chemistries make powder mixing somewhat dicey. The various chemistries in different powders and metal flakes repel each other and create vein and hammertone effects. Textured powders are made by mixing powders of different chemistries after they are ground.

When powder is applied to metal and placed into the oven for cure, it melts together to form a continuous and resilient seal against moisture, rust and corrosion. Unlike paint, powder does not contain chemicals that evaporate during cure -once powder is cured in the oven, it remains flexible. Because it is in the plastic family, powder continues to move with the metal as it expands and contracts with the weather. Paint gets harder as the chemicals that make it liquid evaporate. Once paint cures, it is more likely to chip, crack and peel, allowing the metal underneath to rust. Because of it’s plastic nature and flexibility powder bounces back instead of chipping.

Almost all powder contains UV protectants that help maintain both color and gloss throughout the years. While most paint begins to fade after 1-2 years, powder will stay glossy for 10-15 years or more.

MULTICOLOR POWDER COATING

Acorn Powder Coating carries a comprehensive stock of RAL and BS colours. Our Iron Phosphate process in an inline process using Chemtelle Gardbond A4917 chemical. We can also locate M.O.D colours in powder for components up to 1,500mm x 1,000mm x 550mm, and match any fastener colour (at extra cost) for the construction industry.

The finished product is very aesthetically pleasing and is less prone to to chipping, marking and scratching.

The powder coating process is faster than traditional wet painting where the product must dry between coats. With powder coating, the product is oven baked, so there is no need to wait for drying.

Powder coating is a more environmentally-friendly process, as powder can be recycled.

Powder coating can be applied to a wide range of metals and components and is suitable for both internal and external applications.